Introduction

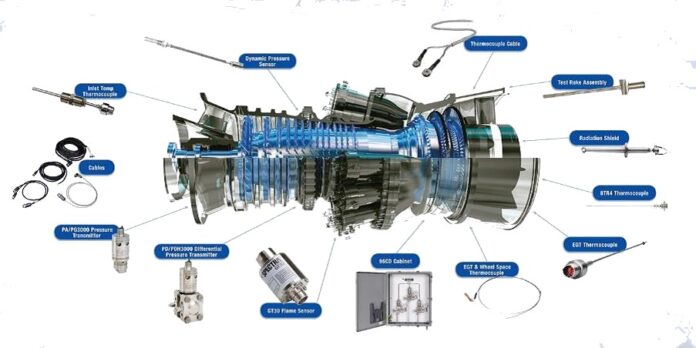

A gas turbine is a type of power plant that uses a combination of fuel and air to generate electricity. The efficiency and reliability of a gas turbine are largely dependent on the quality of its maintenance and repair. This article will discuss the various aspects of gas turbine maintenance and repair, and provide an in-depth understanding of how these processes work.

Maintenance

Gas turbines require regular maintenance in order to ensure they are operating at their optimal performance. Routine maintenance includes checking the fuel system and filters, inspecting the turbine blades, and performing regular oil changes. In addition, the gas turbine must be monitored for any signs of wear and tear.

It is important to note that regular gas turbine maintenance should be conducted even if the turbine appears to be running properly. This is because small maintenance tasks can help to prevent larger problems from occurring in the future.

Types of Gas Turbine Maintenance

Gas turbine maintenance can be divided into two broad categories: preventive maintenance and corrective maintenance.

Preventive Maintenance

Preventive maintenance is the practice of regularly inspecting and servicing gas turbines in order to detect any potential problems before they become serious. This type of maintenance is essential for ensuring the long-term reliability and efficiency of the turbine. Common preventive maintenance activities include visual inspections, cleaning, lubrication, and adjusting parts.

Corrective Maintenance

Corrective maintenance is performed when a problem is detected and requires immediate attention. This type of maintenance is designed to repair or replace components that have failed to prevent further damage. Common corrective maintenance activities include a component replacement, component repair, and component overhaul.

Inspection

Inspection is an important part of gas turbine maintenance. During an inspection, specialists will check for any signs of wear and tear on the turbine components. This includes checking the blades for signs of corrosion, as well as inspecting the fuel system and filters.

In addition to inspecting the turbine itself, specialists will also inspect the surrounding components such as the fuel lines and air ducts. This allows them to identify any potential safety hazards or mechanical issues that could affect the turbine’s performance.

Repair

If it is determined that the turbine requires repairs, specialists will begin the process of repairing the turbine. This includes replacing any damaged components, such as the blades or fuel system. Additionally, specialists may need to repair any electrical components in order to ensure the turbine is operating safely and efficiently.

Cleaning and Lubrication

Cleaning and lubrication are important maintenance activities that help to keep the turbine running smoothly. During a cleaning procedure, the components are cleaned of any dirt or debris that may have built up over time. Lubrication is also important and should be done regularly to ensure the turbine is operating at its optimal level.

Adjustment

Adjustment is another important gas turbine repair procedure. During this process, technicians adjust components such as valves and fuel injectors to ensure they are functioning correctly. This is important for maximizing the efficiency of the turbine and preventing any unexpected issues.

Conclusion

In conclusion, understanding gas turbine maintenance and repair is essential for ensuring the optimal performance of the turbine. Regular maintenance, inspections, and repairs are all necessary in order to ensure the turbine is operating safely and efficiently. By following the proper maintenance and repair procedures, the life of a gas turbine can be extended, and its performance improved.